This is the development of how I made the posters for Design for Print categorised by process.

Digital Printing

I started the processes of making the posters by digitally printing them without the illustrations ready for the illustrations to be printed on them in the different processes.

This is how they looked when going to print. I made sure there wasn't any typos, and took of all of the illustrations so they could be added.

They actually had to be scaled down to 95.87% to fit on the page, meaning all the illustrations I now print to be added, need to be scaled down to that size as well.

I only printed one of each poster because the stock is quite expensive, so I need to make sure I do lots of tests first to make sure I get it right.

Here is how they looked when printed:

Lino

I then printed of the two lino illustrations I have, and I'm going to lasercut one, and hand cut the other so that they fit in with context on the posters.

I stuck the bottom illustration onto the lino so I had an outline to score. I used a scalpel to score it so I knew where to cut.

However, when I was cutting it, I realised I hadn't reversed the image and so I had cut the numbers the wrong way round. This was also very difficult because it was so small, and it wouldn't have been very legible. So now my idea is to lasercut them both, but then use a scalpel to make the cut deeper. This will allow the intricate areas to be perfectly cut, but I can make it deeper so it won't print that area.

I booked another laser cut session so that I could print the two lino cut designs I had. To speed things along, I chose the scan line resolution to be 0.2mm rather than 0.1mm as this means it cuts have as much. This means you will be able to see the lines more on the design, but as I am lino cutting it after anyway, that won't matter.

I went onto Illustrator and converted the colours so that it was the other way round using the global swatch technique we learnt in the creative suite sessions.

I exported it as a grayscale jpeg and imported it into Ethos. I set the engraving options to 'Enable Engraving' and the scan line resolution '0.2mm' and sent it to cut. This is what it looks like in Ethos when inverted:

It needed to be inverted because where it is black, it will be burnt away.

The first lino looked like this when cut:

The first lino took a long time to cut, about half an hour, and I only had 15 minutes left in my session. So I decided to make the scan line resolution higher at 0.6mm so that it would be considerably quicker.

This made the gaps sparser so you can see the raster more. However, it doesn't matter as I will go over it manually.

I picked a navy colour for this print because my other prints have used bright colours at the moment so needed a cool colour to be more varied. This is the paint I rolled out, the roller and lino print:

As I had carved out the lino print it looked like this now, and picked up a lot less ink.

I put packing in the printing press:

Then placed some practice stock and the lino on top of it, and reapplied the packing.

I did a lot of tests to make sure I was getting the right consistency for my actual poster. This was my first print, and I realised I needed more packing so that the press had less space to print and would make a thicker imprint.

It looked like this because there were pieces of lino stuck to the linocut, paired with not enough pressure.

I applied more pressure, and the pieces were then more visible and I realised what they were. I took them off for the next one.

These came out a lot better.

I did a practice go on mountboard, because it needs different pressure to the thinner stock I was using.

Here is what the cut looked like when I cleaned off the ink:

Here is the final poster, I did it twice. I am very happy with the result, and think that it shows a good example of what linoprinting looks like.

For the next print I decided to go with a dark purple, again to break up the bright, warm colours that I've used.

This is what the print looked like inked up:

I did a practice run through the press first:

This is what the lino looked like when I placed it on the real poster to be put through the press:

Here is what the linocut looked like when I cleaned it:

Here is what the poster looked like, and I was really happy with it until I then realised I had made a mistake - this poster is supposed to be hand pressed!

So I began practicing that by using a device to rub the linocut onto paper. It was quite hard at first and wasn't making much of an imprint, til I then realised I was rubbing it on the wrong side.

The next time I did it correctly it worked a lot better.

It was actually really hard and I applied a lot of pressure to make sure I got a good print.

To do it correctly I needed to rub the paper onto the linocut.

Then I tried it on mountboard as well:

However, when it came to the real poster, I needed to place the lino on top of the stock to line it up with the design first, and when I was turning the poster over to rub it, I moved it accidentally so it reprinted leaving marks everywhere. So I decided to use the other poster because I only had two to print on, even though that one is run through a press.

Foiling

I started preparing my screens for the foiling and flocking illustrations, and cleaning the screen was pretty simple because the printroom wasn't busy.

This is what it looked like when I exposed it:

I started by doing the foiling poster, First Class, and I didn't know what metallic foil to use, so firstly I tried three different ones on the icon as it needed less foil. I tried copper, champagne and platinum. I didn't want to use gold or silver as these are the obvious choices, and the others are more subtle.

To do the foiling, all I did was use glue to screenprint onto the stock and then place the foil onto it facing up. Then I put it into the heat press for 12 seconds:

Here is the outcome of the three different colours:

This is platinum.

This is copper.

This is champagne.

I actually like all three of them, but my favourite is the champagne. It is more subtle than the other two, and I think it goes well with the ivory stock.

To register the poster properly, I placed the positive on top of the stock and secured it with a bit of masking tape. Then I secured the screen into the bed, and placed the stock underneath and lined it up. By having the positive on the top, I can see through the screen where the design would go. I then used masking tape to create an outline of where the stock should be on the bed.

I then decided to try using all three of the foils on the same illustration to see what that would look like, as I liked all three of the colours. I placed the stock in the masking tape outline, and used glue to press the design.

I had previously cut up the different foil so that it would fit onto the design, and I put these in their place and put it in the heat press. This is what it looked like:

When I was peeling it off, there was bits of the packing stuck to where there was no foil, and it wasn't very clean. I decided that just one colour would look better and have a cleaner finish.

This is what it looked like with just champagne, which is my final poster:

When I peeled it off it was a lot cleaner than when I used three different foils at once.

I then decided to do the flocking for the Oh, You Meant The Other Type of Flock? poster. I turned the heat up on the heat press, and while I was waiting for that to heat up I registered the bed to the screen ready. To register, I had a positive of the design so that I could see through the screen and line it up like that.

This was the same process, but instead of placing the foil facing up, I placed the flock facing down.

This is what the test run looked like, which worked really well and I'm glad there is no spaces where the flock didn't take to as it would be really noticeable with it being black.

This is what the flock looks like once it's been peeled of:

This is what the final poster looks like:

I am very happy with the outcome of the foiling and flocking posters as I only had one poster to do it on, and it worked well.

Screenprinting

I used a couple of screens to get all the illustrations on, and this was again a simple process because the printroom wasn't busy.

For the Rush Hour poster, I wanted to do a colour overlap. I wanted to use two colours that would work well together when mixed, so two primaries that make a secondary would be ideal. I looked at left over paint pots in the printroom, as this would be cheaper for me and there is a lot of choice. It also wouldn't matter that there isn't a lot of paint as I am only doing one poster. I found a red and blue that complimented each other well, and would make a purple. However, I didn't want it to look like I was separating genders by colour as the purpose isn't about that - I just like these two colours together. So I thought about having the females in blue, and the males in red.

Here is the blue screenprinted females. I needed to do the layers separately so that they could overlap on the same piece of stock.

When I went to print the red on top, I asked Neil if the inks should be more transparent because I thought with them being thick it might not work. He said that process colours (Cyan, Magenta, Yellow) work best because they have a transparency to them.

So I decided to scrap this blue and try again. I made a blue and a yellow and tested these out.

I was apprehensive beforehand about using these colours as they are very bold, and when I printed them I definitely didn't like them. However, I didn't want to use magenta and cyan as these have too much association with gender, and that isn't what I wanted to portray.

So I thought about keeping the yellow, and trying the red I had originally found. I also wanted to try a couple of other shades of red to see what transparency would work best, if it would work at all. I tried having red underneath, and then with yellow underneath. The best combination was when the red was underneath because it is thicker.

I did a few test runs of what it would look like, and here is one of them.

This is what the poster looked like when just the red illustration was on it.

Originally, I was going to do the Dont Be A Rabbit In The Headlights poster in monoprint, but because of the difficulty I had when doing this process for the icon, I decided that I should just screenprint it instead. As it is just showing that there are fluorescent inks, it wouldn't matter what process it was in - I just originally wanted two posters for each process I talked about on the cards.

I had a look at different fluorescent inks, and saw a red, green and orange. I looked at these and put them next to the stock to see what would look best. I decided to go for the red as it was the most appealing colour in my opinion and I think it would stand out against the ivory.

I did a couple of runs on normal paper firstly, and realised that the ink was really thin and quite light. This is because there is a lot of binder in the ink which makes it more transparent.

To solve this, I added more acrylic to the paint and tried that. This was a lot better, and the print came out a lot thicker and brighter. It needed to be bright because it is to show of fluorescent inks.

Here is the final poster for it:

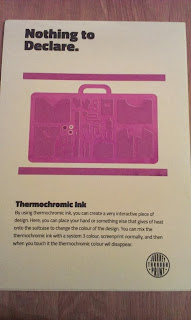

For the Nothing To Declare poster, I wanted to use thermochromic ink. I wanted the suitcase to be a block colour, then when you put your hand over it, it would reveal the contents.

Making the inks was tricky. I had to make the reactant ink by mixing Red and Cyan to create a purple, but this didn't work as it created a murky brown. So I then mixed Magenta and Cyan to make a purple which looked a lot better.

Then I had to recreate a System 3 colour to look exactly the same as the reactant ink colour. I did this after a lot of testing.

I then printed both of the illustrations in the System 3 colour to see what it would look like with this on the bottom on both versions.

I then added the reactant ink on top, and this didn't work at all as the transparency of the inks made it overlap and be very visible.

However it still worked when you put your hand over it, and I love the pink colour it produces.

I then tried the heat reactant as the base, and added the top layer in a spot varnish because it is very transparent and hopefully this would not be as visible. However it was quite visible when I printed it.

I tried putting my hand over it, but the varnish hadn't worked as a protective cover and the heat went straight through it so everything turned pink.

I'm going to try a third attempt now, and this involves making another screen. Instead of creating a mask, I'm going to create an inverted version of the suitcase so that it will slot together as one image. As I have made both of the colours the same I don't have to worry about mixing them, just creating the new screen.

I then figured out a new way I could do it - rather than making a mask, just make the negative of the baggage so that I can just line it up extremely carefully and mimic the same colour.

Here are both my pots of colour when I've tried to mix them to the same colour:

I lined it up on the true grain and printed so that I had my registration, and tried the system 3 ink first.

When I printed the poster, it was clear that the two colours weren't the same still. So, I decided to give up on trying to make this work, and instead change the wording on the poster slightly. I changed it so that it just said the colour changes, rather than reveals the luggage, this way the poster didn't have to act as a mask. I was much happier doing this because it was a lot easier and still meant the message got across. Here are the final poster:

This is a lot deeper because I ran the ink over twice.

Lasercutter

I need to lasercut some more things for the illustrations, which include the embossing and mono print illustrations.

This is the embossing plate, and I'm going to cut it onto MDF 3mm, as this is stronger than mountboard, and when embossing, the plate needs to be stronger than the stock. On the design I needed to make the shapes surrounding more designs not complete, otherwise it would cut straight through the design would be in pieces, when I need it to be one piece.

This is what it looks like when I set the option 'Cut Through' on Ethos.

This is the monoprint stencil, which I'm going to print onto card 220gsm, as it will be light enough to peel off the plastic plate when monoprinting, but strong enough not to break.

This is what the monoprint stencil looks like on Ethos when ready to cut:

Embossing

As I was lasercutting the stencil for the embossing poster, Get Stamped, here is the outcome of that. When I first tried to lasercut it, it didn't go very well. It was taking very long so I had to stop the cut as my session was over. It was just as well it didn't complete because I hadn't made the gaps big enough and when I took it out the lasercutter, the design fell apart. I learnt that I needed to make the gaps bigger next time.

I then redid it, and made the gaps bigger so that it wouldn't fall apart. This worked a lot better.

I tested out the stencil on some mountboard, and it worked well at 4000psi. Although I would like it to be more prominent, the stock isn't very elastic so isn't as obvious as it would be on paper.

I then embossed onto the poster and this is how it turned out. I am happy with it, and I know that with this stock I couldn't get a deeper imprint, but next time I will definitely choose a different stock so that it is a lot deeper.

Monoprinting

I also lasercut the monoprint stencil for the poster, From Paint to Press in 10 Minutes, and this is what it looks like. I think this will be an easy poster to create as creating a colour blend is a quick process, especially as I am just using one layer.

I used green and blue ink and rolled them together to create a gradient.

I then rolled the ink onto a plastic plate, put the stencil on top and placed it on the press.

I then I put the poster on top in line with the stencil.

I put packing on top of this, and rolled it through the press.

I tested it onto paper first, and was happy with the gradient, so went ahead with the final poster.

I did two versions, one with more pressure applied than the other. I am happy with these two prints, although I would have preferred the colours to have been lighter. The reason I didn't do them lighter was because 1. there was no lighter choice and 2. I didn't want to mix them because it would have been quite hard given the texture of the paint and I didn't want to waste it as I was putting excess paint back in the tin.